SDN Series

Supertec's SDN Series holds one of the highest standard of solutions.

Stepping up the game to a whole new level

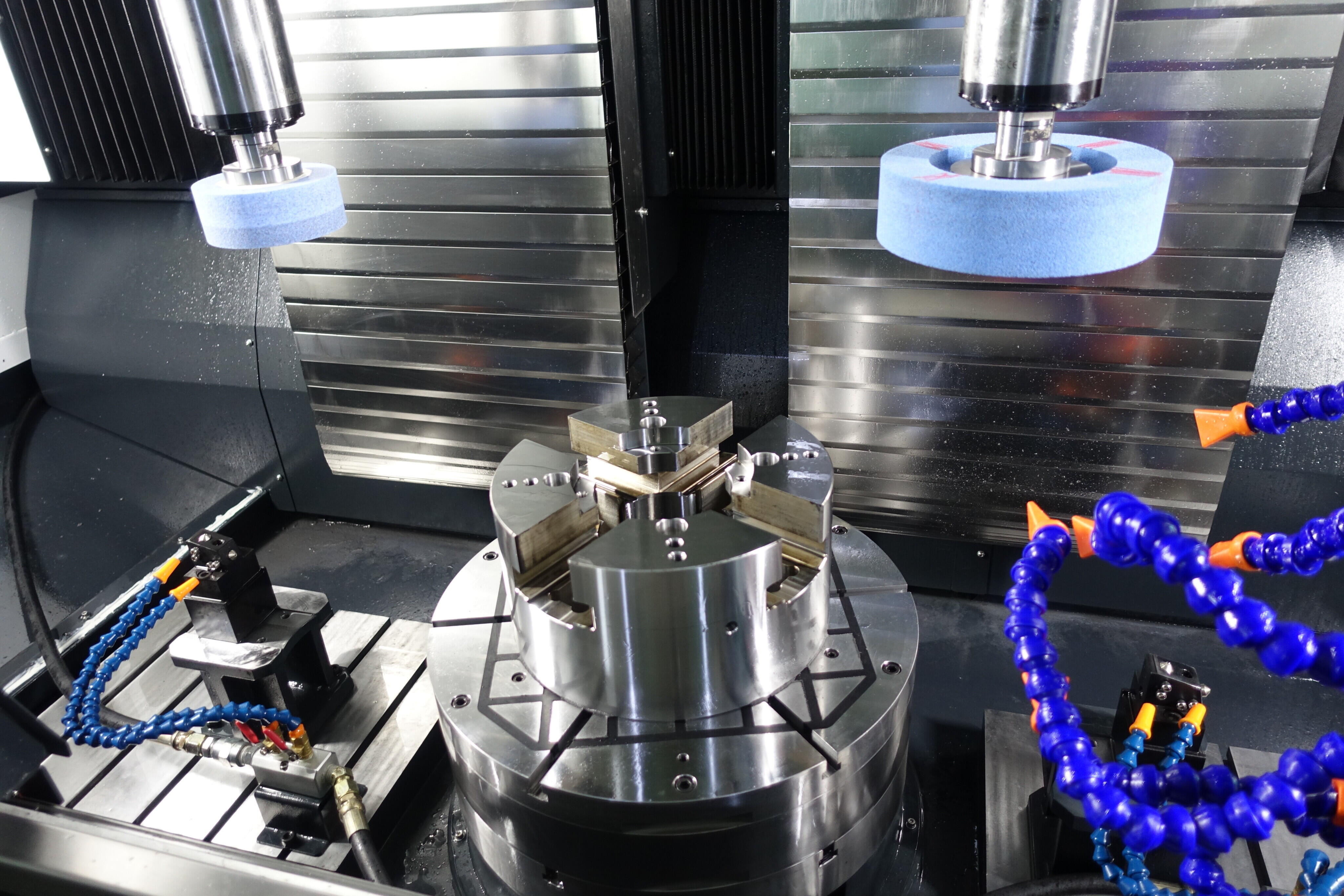

This machine can complete all three OD ID & End face grinding in one chucking for HEAVY or NON-CIRCULAR work pieces.

The SDN Series is made for Heavier work pieces, it can EASILY be loaded to the machine by the overhead hoist.

Fully enclosed covers and oil mist reclaiming guarantees to keep the factory and the machine nice and clean.

Options : 1. single/double-spindle with or without tool changer.

Fanuc controller plus 10" screen man-machine touch panel.

Simple conversational operating system all programmed and allows machinist to machine workpiece with instinct.

Description

SUPERTEC SDN Series

For the past 70 years, Supertec has developed many solutions and the best machine configuration for our customers within 6 months. Supertec total solution covers machining process, type, Jig, grinding wheel, into account, we have been creating professional all-round plans and high production efficiency. The difference of Supertec’s solution and others is that we take the issue of energy saving more seriously and carefully, that is what we called “The Complete Turnkey Solution” When it comes to turning grinding, boring grinding, speed shifted compound grinding, varied type grinding, gear grinding, eccentric grinding, or end tooth grinding, Supertec will be your best and only choice.

Here are some obstacles-that others might have a hard time with, but on the contrary it spotlights our brilliant advantages as below;

01. For Spindle Quill Grinding:

Since the accuracy of the concentricity, roundness and the cylindricity for spindle quill grinding will impact the machining efficiency. Supertec knows how to choose the best grinders for our customers and set up the proper fixtures and the precise repeatability of work piece clamping. Not only raises the machining efficiency, but also greatly shortens the cycle time. After all, time is money! Supertec SDN Series could show the excellent design for customers by customized fixtures and human-based dialogue software.

02. For Varied Type Grinding

The controller, proper machine model and transmission mechanisms will decide the accuracy of varied type grinding. Supertec’s vertical grinders made the best vary contouring grinding and guarantee its accuracy within 2μm through non-backlash transmission mechanism with DD motors, hydrostatic rotary table and professional programs under Fanuc/Siemans controllers.

03. Minimum Tolerance Of Precise Grinding

Fixtures design, mechanism structure, grinding wheel material and machining method are the key point to affect grinding accuracy. Supertec SDN Series could keep the grinding accuracy within 1μm and have the minimal feed rate to 0.1μm by professional skill, experience and the know-how of assembly accuracy control.

04. Machines Reliability

Supertec builds high qualities and reliable grinders for using with high rigid mechanism, serious equipment and inspection main components and every phases of assembly. Even the optional accessories, we choose carefully to make sure and reach to customer’s demand.

05. The Advantages Of Structure Design

a. Supertec Vertical Grinders is designed with special double column structure, which will keep the machine steady and rigid. X axis has four heavy duty types of roller type linear guideways, make machine strong and sound during movement

b. High precise turning table located solid on base keep displacement away between components.

c. Transmission mechanism is separate from cutting area to keep main mechanism away from dust and chips.

d. The lower gravity base structure stables the accuracy and makes machining easier.

e. Our flexible design team could customize complex machines such as dual spindles, dual ATC, etc..

06. The Brand Of Main Components

By using Swiss liner guideways and German Ball screws, we can get the accuracy at 1μm of straightness within whole travel and 2μm of perpendicularity of axes.

Axes orientation could be within 3μm and 2μm of repetition orientation accuracy. X axis and C axis can synchronize and the contouring accuracy within 2μm via linear motors and non-backlash ball screws.

Features

This machine can complete all three OD ID & End face grinding in one chucking for HEAVY or NON-CIRCULAR work pieces.

- The SDN Series is made for Heavier work pieces, it can EASILY be loaded to the machine by the overhead hoist.

- Fully enclosed covers and oil mist reclaiming guarantees to keep the factory and the machine nice and clean.

- Options : 1. single/double-spindle with or without tool changer.

- Fanuc controller plus 10" screen man-machine touch panel.

- Simple conversational operating system all programmed and allows machinist to machine workpiece with instinct.